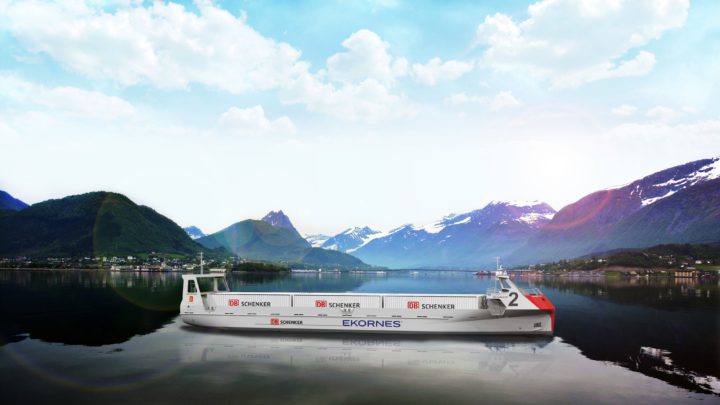

The fully electric vessel has a unique design, making it the first of its kind in the world. Having just signed a prestudy agreement, DB Schenker and its cooperation partners – the furniture giant Ekornes and the vessel designer Naval Dynamics, along with KONGSBERG and Massterly – have taken the first steps in the ambitious joint project to replace the traditional feeder vessels utilised along the stretch of the Norwegian coastline around Ikornnes and Ålesund.

The new autonomous and electric, short-sea container feeder leverages Naval Dynamics’ NDS AutoBarge 250 concept that was developed in partnership with KONGSBERG and Massterly.

The vessel will operate between Ekornes’ own port, Ikornnes, and the port of Ålesund, which serves the main ocean freight ports in Europe. The ship will complete the 43-km (23-NM) journey within three hours, at a speed of 7.7 knots.

Game-changer in the ocean fright sector

The vessel will be 50 meters long and will be able to carry 300 deadweight tons of cargo. It is designed from the keel up for autonomous and zero-emission operation. It will run without a crew but will be monitored and controlled by staff at Massterly’s Remote Operation Center (ROC), whose team members include certified navigators and naval engineers. The planned two-way data communication solution between the vessel and the ROC is destined to be another game-changer in the ocean freight sector.

“We are delighted to be further intensifying an already strong relationship with our customer Ekornes. This unique project marks another important step toward greener supply chains, and it also fits in perfectly with our overall sustainability agenda in ocean freight, where we are ambitiously taking the lead with our cooperation partners,” said Knut Eriksmoen, CEO Norway, DB Schenker.

Roger Lunde, CEO, Ekornes AS: “We’re continuously working toward our goal of becoming the world’s leading manufacturer of sustainable premium furniture. With this landmark project, we will meet our sustainability targets by using the most innovative technology available. Utilizing the autonomous electric container feeder for direct pickups of our Stressless products from our own dock in Ikornnes means that our total carbon footprint will be reduced significantly. We will also gain better control over, and greater flexibility with, our own logistics.”

Pioneering work

Geir Håøy, CEO, KONGSBERG ASA, said: “We’re beginning to see a general shift away from road transport of goods – with its considerable carbon footprint – toward clean, energy-efficient, short ocean freight transport. Given our decades of expertise in creating and perfecting systems for ship operations in every context, we are in a unique position to carry out pioneering work in this project. KONGSBERG is currently involved in several fully electric and autonomous vessel operations, including Yara Birkeland and ASKO. We look forward to contributing our expertise and experience to this new partnership with DB Schenker and Ekornes.”

Tom Eystø, managing director, Massterly, said: “We are very pleased to be working with Ekornes and DB Schenker to create a smart logistics solution for the Ekornes production site. The small, fully electric, and energy-efficient cargo vessel will be designed for uncrewed operations. Massterly will operate the vessel from our Remote Operation Center. We find it very interesting that one of the world’s largest logistics providers, DB Schenker, is recognising the benefits offered by uncrewed, zero-emission shipping, and we hope this project will inspire a larger volume of similar vessels.

Øystein Jaer, CEO, Naval Dynamics AS, said: “The AutoBarge 250 Coast Feeder is designed from the keel up for efficient and zero-emission autonomous operations. In partnership with Massterly AS – the vessel operator and technical manager – and Kongsberg Maritime AS – the technology provider – we are confident that DB Schenker and Ekornes will be provided with an optimal and viable transport chain that will meet the future demands of customers around the world.”