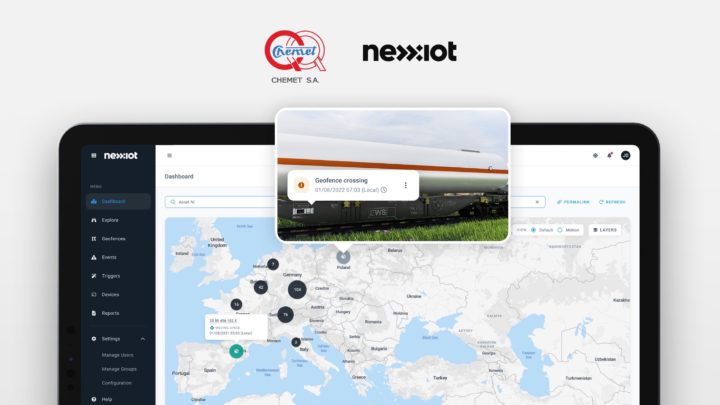

CHEMET, based in Poland and France, is the first European manufacturer to commit to fully digitalising its railway tank car offerings.

CHEMET will integrate Nexxiot’s Asset Intelligence technology into newly manufactured railway tank cars. CHEMET’s clients will be able to access the real-time location of equipped railway tank cars, monitor total mileage, and shocks, and receive notifications if the tank experiences significant temperature changes.

Nexxiot’s sensors and data analytics also provide advance notice of adverse conditions, preventing greater damage and losses.

“We want to celebrate CHEMET’s bold move to fully digitalise their manufactured tank cars,” said Stefan Kalmund, CEO of Nexxiot.

“The deployment is an important step in the digitalisation of tanks and sets an example for the industry to aspire to.”

Increased desire for digitalisation

“Our customers have expressed an increased desire for digitalisation, and we want to ensure that their needs are being met,” said Bartosz Urbaniak, commercial operations director of CHEMET.

“Partnering with Nexxiot allows CHEMET to offer fully digitalized tank cars and eliminates the need for our customers to undergo the rigorous process of identifying, mounting and coordinating the rollout of new technology themselves.

“CHEMET manufactures the safest railway tank cars available today, and with the addition of Nexxiot’s technology, our customers will benefit from smarter and safer tank cars that are rail-ready right off the manufacturing line.”

CHEMET focuses on serving the European tank cars market, producing annually up to 500 complete tank cars and up to 1,000 tanks for the railway industry designed for transportation of dangerous goods (LPG, ammonia, chemical products) for leading rail clients including ERMEWA, ARETZ and GATX Europe.