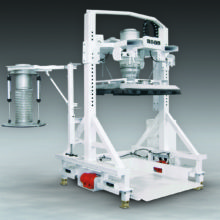

The filler uses the company’s patented Twin-CenterpostT frame claimed to maximise strength and improve accessibility to the fill head while simplifying construction and reducing cost.

It is mounted on load cells tied into a PLC that controls upstream devices to fill containers at high rate, and then at dribble-feed rate to maximise the number of containers filled per hour, while still achieving required accuracies.

An automated vibratory system raises and vibrates the container deck to de-aerate and densify material, stabilising the container. The low-profile configuration of the filler also allows removal of filled containers using a pallet jack, eliminating the need for a fork truck.

Bulk bag-filling-related features include manual fill head height adjustment to accommodate all popular bag sizes, pneumatically-retractable bag hooks, an inflatable connector to seal the bag inlet spout and a feed chute outlet port for dust-free air displacement during filling.

Quick-action clamps connect the transition hood to the fill head for filling boxes from 915mm to 1,220mm on a side and overall height of 990mm to 1,117mm. For filling drums from 114-208 litres, a pneumatically-actuated, telescoping drum filling adapter swivels inward for rapid connection to the fill head using quick-action clamps, after which an inlet plate is sealed against the rim of the drum.

In all cases, filling cycles are initiated with a manual push button or by electrical contact closure, after which filling, de-aeration and any required disconnection of the equipment from the container inlet are automatic.

The filler is constructed of carbon steel with durable industrial finish, or stainless steel finished to industrial, food, dairy or pharmaceutical standards, and is offered with a mechanical or pneumatic conveyor delivery system integrated with the user’s upstream process equipment or other material source.

The company also manufactures bulk bag dischargers, bulk bag conditioners, drum/box/container dumpers, bag dump stations, weigh batching and blending systems, and engineered plant-wide bulk handling systems with automated controls.