In the nomenclature of the fuel-hauling industry, a ‘cross-drop’ is an event that occurs when a transport-truck driver accidentally unloads the wrong fuel product into the wrong underground storage tank (UST) during a delivery to a retail- or commercial-fuelling location.

The ultimate effect of a cross-drop is the shutdown of the fuelling site for several hours as the now unsalable fuel is removed and the tanks are cleaned, which will lead to lost revenue and significant maintenance and disposal costs. Not to mention the damage to the retailer’s reputation.

“Some of the stores we service have 40,000-gallon tanks, so a cross-drop for us isn’t just 5,000 or 6,000 gallons,” says Terry Tesch, general manager for RB Stewart Petroleum Products, of Angleton, Texas. “When you’re talking about 40,000 gallons, a cross-drop dramatically increases the cost of clean-up, and for a store that size, a clean-up can cost as much as US$100,000.”

Knowing this, it’s no wonder that many fuel suppliers consider a cross-drop – despite its nine-letter length – to be the ultimate proverbial four-letter word in their business.

Getting the drop on cross-drops

Founded in 1932 by Guy Stewart in Angleton, about 45 minutes due south of Houston, RB Stewart has grown into one of the leading transporters of refined fuel products for the eastern half of Texas, and is in the midst of an ambitious plan to grow its supply network beyond the borders of the state.

“We currently have 75 power units, 75 trailers and employ 133 drivers; we’ll deliver more than 500 million gallons of fuel in a normal year,” explains Jim Wallace, RB Stewart’s maintenance manager. “We’ll also be in multiple states in the Southeast in the next 18 months, and we’re very excited about that.”

In nearly 90 years of operation, the threat of the cross-drop has been a constant companion for RB Stewart, as it is for all fuel transporters. In fact, industry studies regarding tank-truck usage patterns across the United States show that the unintended mixing of octane types at a fuelling site happens once in every 14,000 deliveries nationally, with a diesel/gasoline mix-up occurring once in every 45,000 fuel drops across the country.

Cross-drops generally take place when, or if, a driver accidentally runs a hose from a trailer compartment to the incorrect storage tank. A cross-drop may also take place when the product types are not clearly marked on the storage tanks. Rudimentary attempts to combat cross-drops have included the development of a routine where the driver always unloads diesel first, or outfitting trailers with manually adjustable product grade indicators (PGI) that are reset by the driver after a delivery has been completed. The effectiveness of these safeguards can be compromised if the driver is rushed or distracted.

The ways to prevent cross-drops have understandably grown over the years as fuel-delivery monitoring technology has advanced and become more sophisticated. One of the most significant technological advancements of the past five years was the development of the Cross-Over Prevention Systems, or COPS, by Civacon, a Hamilton, Ohio-based developer of products and systems for the safe loading and unloading of petroleum, dry-bulk and petrochemical cargo tanks.

COPS was designed to remove human error from the fuel-delivery process through the use of a Smart Elbow connection to the UST and a hose connection to the trailer. A signal from an RFID tag attached to the UST is wirelessly sent to the trailer’s fuel-control system. If the information from the RFID tag does not match the proper product grade from the trailer, the delivery could not be initiated.

An early adopter of the COPS system for its delivery fleet was RB Stewart.

“We really like to take advantage of new products and technologies,” says Pete Petrosky, president of RB Stewart. “In 2017, we got involved with the COPS system and it really worked well for us.”

Taking command

The evolution of technology is constant, so while COPS and its Smart Elbow product-grade identification system was an undeniable breakthrough in cross-drop prevention, it would soon become just another cutting-edge component that can be used in conjunction with Civacon’s next revolutionary fuel-delivery innovation – the CivaCommand Smart Tank System, which was fully introduced to the market in 2019.

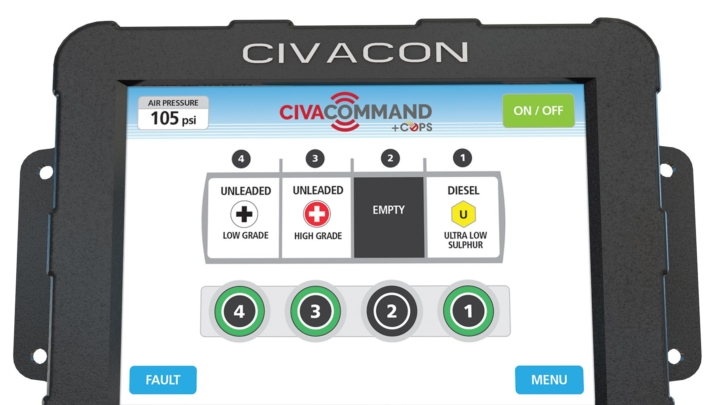

CivaCommand is a highly engineered, easy-to-use solution that consolidates access to the different control systems on the trailer – including cross-drop prevention, on-board overfill-prevention monitoring, pneumatic (air pressure) control, security, electronic PGIs, troubleshooting and usage history. The driver interacts with the trailer by using a digital touchscreen display for loading and unloading activities.

The digital touchscreen can be securely activated by the driver – even while wearing gloves – through the entry of a unique user ID and PIN. The system becomes active during loading when the driver attaches the grounding cord to the receiving socket on the trailer at the loading terminal. Once the grounding cord is connected, the system will send a ‘permit’ signal to the load rack that allows loading to commence. The CivaCommand system is designed to alert the driver if the trailer fails to ‘permit’ and communicates the reason(s) why to the driver through on-screen dialogue. The trailer will only be allowed to load once active ‘non-permit’ issues have been resolved.

Smart Elbow

CivaCommand will allow for unloading once a match is made between the Smart Elbow and the RFID tag attached to the UST. When the Smart Elbow is properly cammed to the UST fill pipe, it sends a wireless signal to the system, automatically unlocking matching product unload heads and internal valves that allow fuel to be unloaded from the trailer. At the conclusion of the unloading process, the touchscreen communicates to the driver that each compartment is empty, which indicates that hoses, elbows and adaptors can be safely disconnected. ‘Empty’ status is also stored in the system memory in case the fuel delivery is questioned by the customer. Smart Elbows may also be used for USTs that are not equipped with RFID tags.

“After the success we had with COPS, we were eager to see what the CivaCommand could do for us,” says Tesch.

RB Stewart has devised a three-pronged approach to getting its fleet outfitted with the CivaCommand system:

- All trailers that were outfitted with COPS have been upgraded to the CivaCommand system

- CivaCommand will be specified on all new trailer purchases

- All existing trailers will be retrofitted with CivaCommand by the end of 2022

Boon for drivers

“We currently have 37 units with CivaCommand, and everything we order on new trailers will now be equipped with CivaCommand,” adds Tesch.

The implementation of the CivaCommand system has also been a boon for the ones that it benefits the most – the drivers on the front line who wage the daily battle against cross-drops.

“It’s been a ‘no big deal’ for the guys with CivaCommand on their trailers; they’re used to us throwing things at them,” said Wallace. “They’ve gotten comfortable with the system quickly and understand the reason for the investment.”

RB Stewart’s rapid acceptance of CivaCommand and the acknowledgement of its future potential have created a hand-in-glove relationship between the company and Civacon, with RB Stewart piloting the new technology through real-world use that can provide feedback about how the system works in the field.

“RB Stewart knows that having a delivery with a cross-drop is extremely disruptive and expensive, and that’s the primary driver for why they’ve gone with CivaCommand and its cross-drop prevention capabilities,” explains Scott Mehman, Midwest Region Accounts Manager for Civacon. “They’ve learned to appreciate that it’s a digital system that provides real-time information, and they’ve learned to appreciate the ancillary features, like retain warnings and overfill-prevention diagnostic functionality. They’ve been tremendous partners in the development of CivaCommand, allowing us to understand what additional refining may be needed to create a better product for the next generation.”

Technologies that create efficiencies

The folks at RB Stewart also value the relationship that has been built between the company and Civacon.

“We’ve got to hand out some kudos to Civacon,” Wallace says. “Every time we’ve picked up the phone and called, those folks have answered it and helped us to very aggressively work through any challenges. The communication gets better every day. Our people are more self-sufficient than they were a year ago and that’s due not only to the people here, but at Civacon. When we take these leaps of faith, Civacon has been right there with us.”

“What made us want to invest the money in the CivaCommand system was the new technology that came with it, and would continue to come with it down the road as we evaluate the performance of not only our equipment, but our people,” says Petrosky. “CivaCommand allows us to step up our game; we like to think we’re a different breed in the trucking world and that we’re not afraid to try new technology and pieces. We focus on technologies that create efficiencies, and the CivaCommand fits right into that mindset.”

Mark Dudley works for Civacon, based in Hamilton, Ohio, and has 15 years experience in the fuel-transport industry, including involvement in advancing fuel-delivery technology